Embark on an educational journey with our comprehensive mass hoisting license study guide. As you delve into the world of mass hoisting, you’ll gain invaluable knowledge and skills to operate equipment with precision and ensure workplace safety.

This guide provides a roadmap to understanding the intricacies of mass hoisting, covering topics such as rigging techniques, load handling principles, and electrical hazards. Prepare yourself for success and earn your mass hoisting license with confidence.

Introduction

Obtaining a mass hoisting license is crucial for individuals working in industries that utilize heavy machinery. This license ensures that operators possess the necessary knowledge and skills to safely and efficiently operate mass hoisting equipment, minimizing the risk of accidents and ensuring the well-being of personnel and property.

Mass hoisting equipment encompasses a wide range of machinery used for lifting and transporting heavy loads, including cranes, hoists, and derricks. These machines find applications in construction, manufacturing, mining, and various other sectors where heavy objects need to be moved.

Types of Mass Hoisting Equipment

- Cranes:These are used for lifting and moving heavy objects in various settings, including construction sites, factories, and ports. They come in different types, such as mobile cranes, tower cranes, and overhead cranes.

- Hoists:Hoists are designed for lifting and moving loads vertically. They are commonly used in construction, warehouses, and manufacturing facilities.

- Derricks:Derricks are similar to cranes but have a fixed mast and a boom that can be raised or lowered. They are often used for construction projects and offshore operations.

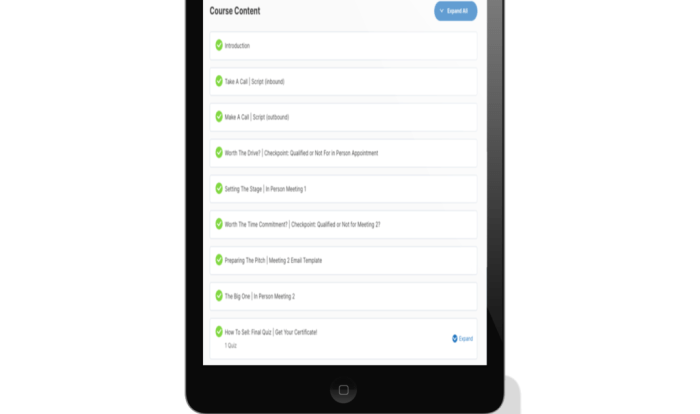

Study Guide Overview

The mass hoisting license study guide is a comprehensive resource designed to prepare individuals for the licensing exam required to operate mass hoisting equipment.

The guide covers a wide range of topics essential for safe and efficient operation of mass hoisting equipment, including:

General Knowledge

- Understanding the principles of mass hoisting equipment.

- Types of mass hoisting equipment and their applications.

- Safe operating procedures for mass hoisting equipment.

- Common hazards associated with mass hoisting operations.

Equipment Components

- Major components of mass hoisting equipment, such as the hoist, boom, and rigging.

- Functions and interactions of each component.

- Proper maintenance and inspection of equipment components.

Rigging

- Types of rigging used in mass hoisting operations.

- Safe rigging practices, including load calculations and proper sling selection.

- Inspection and maintenance of rigging equipment.

Load Handling

- Principles of load handling, including load stability and center of gravity.

- Techniques for lifting, moving, and placing loads safely.

- Load handling hazards and mitigation strategies.

Safety Regulations

- Applicable safety regulations and standards for mass hoisting operations.

- Responsibilities of the operator and other personnel involved in mass hoisting.

- Emergency procedures and incident reporting.

Rigging and Equipment

Rigging plays a pivotal role in mass hoisting, providing the essential means to connect and support loads during lifting operations. Understanding the various types of rigging and adhering to proper inspection and maintenance procedures are crucial for ensuring safety and efficiency.

Rigging encompasses a wide range of components, including slings, shackles, hooks, and wire ropes. Each type serves a specific purpose and has unique characteristics that must be considered during selection and use.

Inspection and Maintenance

Regular inspection and maintenance of rigging are essential to identify potential hazards and prevent failures. Inspections should be conducted by qualified personnel who are familiar with the equipment and applicable standards.

Thorough inspections involve examining rigging for signs of damage, wear, or corrosion. Any defects or irregularities must be promptly addressed to prevent catastrophic failures during lifting operations.

Proper maintenance includes lubrication, cleaning, and storage of rigging equipment. Lubrication reduces friction and wear, while cleaning removes dirt and debris that could compromise the integrity of the rigging.

Proper storage practices help prevent damage and prolong the lifespan of rigging. Storing equipment in dry, well-ventilated areas protects it from moisture and environmental factors that can lead to corrosion.

Load Handling

Load handling encompasses the principles and procedures involved in safely lifting, moving, and securing loads during mass hoisting operations. Understanding these principles is crucial for ensuring the safety of personnel, equipment, and the load itself.

Safe operating procedures for lifting and moving loads require meticulous planning, coordination, and execution. These procedures include:

Planning

- Conducting thorough risk assessments to identify potential hazards and develop mitigation strategies.

- Selecting appropriate lifting equipment based on the load’s weight, dimensions, and rigging requirements.

- Establishing clear communication channels and protocols among all personnel involved in the operation.

Execution

- Using proper lifting techniques and equipment, such as slings, shackles, and hooks, to ensure the load is securely attached.

- Maintaining a safe working load limit for the equipment and rigging components.

- Coordinating the lifting and moving operations smoothly, avoiding sudden movements or excessive force.

Securing

- Stabilizing the load once it has been lifted and moved to its destination.

- Using appropriate securing devices, such as chains, ropes, or straps, to prevent the load from shifting or falling.

- Inspecting the load and securing devices regularly to ensure they remain in good condition.

Electrical Safety

When operating mass hoisting equipment, it is crucial to be aware of the electrical hazards that can arise. These hazards can include electrical shock, burns, and explosions.

To prevent electrical accidents, it is essential to take the following precautions:

Electrical Safety Precautions

- Never operate mass hoisting equipment without proper training.

- Inspect the equipment before each use to ensure that it is in good working order.

- Never use damaged equipment.

- Keep all electrical connections dry and clean.

- Never overload the equipment.

- Follow the manufacturer’s instructions for operating the equipment.

- Be aware of the location of all electrical hazards in the area.

- Wear appropriate personal protective equipment, including rubber gloves and boots.

Licensing Requirements

Obtaining a mass hoisting license is essential for individuals who wish to operate or supervise mass hoisting equipment. The licensing process typically involves meeting certain eligibility criteria, completing training, and passing an examination.

The specific requirements for obtaining a mass hoisting license may vary depending on the jurisdiction or regulatory body. However, some common requirements include:

Eligibility Criteria

- Minimum age requirement (usually 18 or 21 years old)

- High school diploma or equivalent

- Good physical and mental health

- No history of major accidents or violations related to hoisting operations

Training and Examination

- Completion of an approved training program covering topics such as rigging, load handling, electrical safety, and hoisting equipment maintenance

- Passing a written and/or practical examination demonstrating knowledge and skills in mass hoisting operations

Study Tips: Mass Hoisting License Study Guide

Preparing for the mass hoisting license exam requires a strategic approach. Follow these tips to enhance your study efforts and increase your chances of success.

Practice and preparation are crucial for success. Dedicate ample time to studying the exam material, and take practice tests to familiarize yourself with the question format and assess your knowledge.

Exam Preparation

- Review the study guide thoroughly, paying attention to the key concepts and regulations.

- Attend training courses or workshops to supplement your self-study.

- Study the reference materials provided by the licensing authority.

- Join study groups or online forums to connect with other candidates and share knowledge.

Practice Tests

- Take practice tests under timed conditions to simulate the actual exam experience.

- Review your answers carefully and identify areas where you need improvement.

- Seek feedback from instructors or experienced professionals to enhance your understanding.

- Repeat the practice tests until you consistently achieve passing scores.

Time Management, Mass hoisting license study guide

- Create a study schedule and stick to it as much as possible.

- Break down the study material into smaller, manageable chunks.

- Take breaks during your study sessions to avoid burnout.

- Prioritize the most important concepts and allocate more study time to them.

Mindset

- Stay positive and motivated throughout the study process.

- Believe in your ability to pass the exam.

- Don’t be afraid to ask for help when needed.

- Visualize yourself successfully passing the exam.

Common Queries

What types of mass hoisting equipment are covered in the study guide?

The guide encompasses a wide range of mass hoisting equipment, including cranes, hoists, and rigging.

What are the key safety considerations when operating mass hoisting equipment?

Rigging inspection, load assessment, and electrical hazard awareness are among the critical safety aspects addressed in the guide.